What’s the future of robotics without reliable motion solutions? That was the big question at RoboBusiness, where industry leaders came together to explore how innovation is shaping the next generation of robotics. Dive into our recap of the key moments that are driving the future of automation forward.

Manufacturing

-

Read more »

-

Posted: October 09, 2024||Read more »Forget dusty factories – today's manufacturing is a high-tech wonderland of opportunity. Discover how a career in this innovative field could be your gateway to shaping the future while enjoying stability and growth.

-

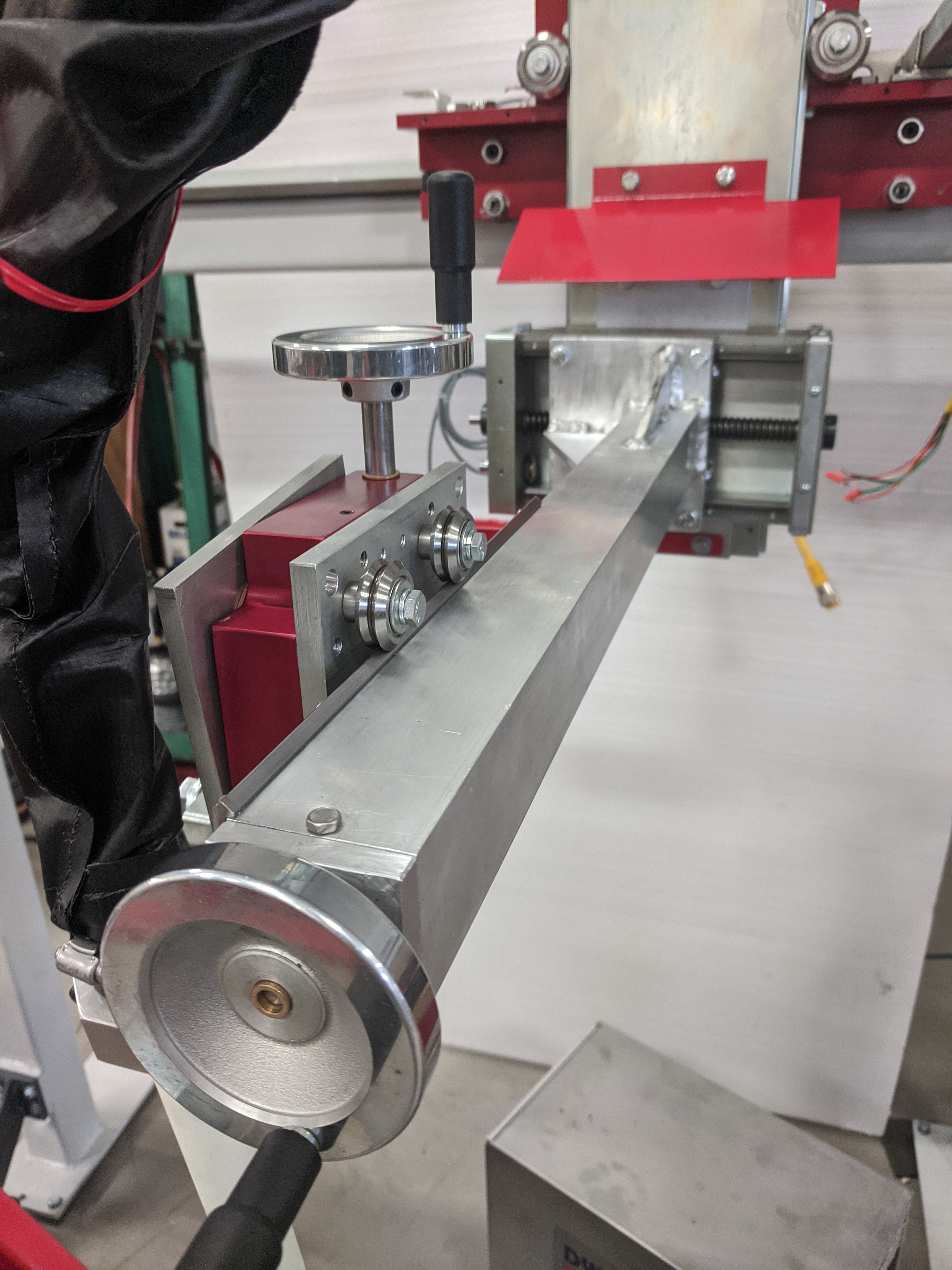

Posted: December 29, 2021||Read more »If you can’t stand the heat, get out of the kitchen. Or in this case, if your products can’t withstand the heat, step aside as this is where Bishop-Wisecarver excels. Just ask our long-time customer, Mavrix Welding Automation of Wisconsin. Mavrix designs and builds standard and custom machines for special purpose welding and fabrication. Their customers include agriculture, oil & gas, recycling, and steel manufacturing industries that need robust and durable machines built to last.

-

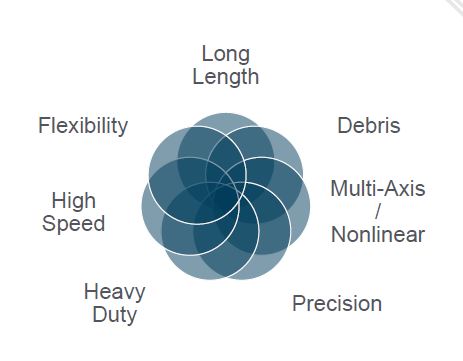

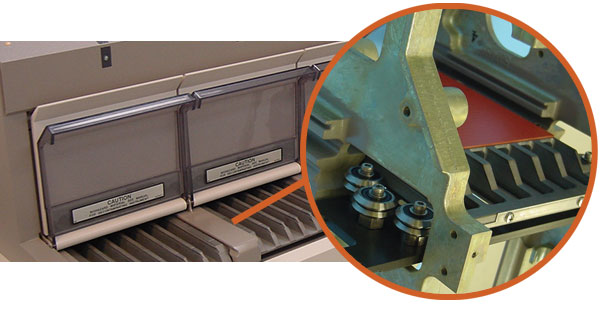

Posted: June 30, 2021||Read more »What do 7th axis robots, indexing assembly lines, and pick-and-place gantries have in common? They all count on reliable transfer technology.

-

Read more »Loop. Shag. Pile. Plush. Deciding on the type of carpet and the color, and then researching how to get out wine stains and muddy paw prints, is the extent of knowledge most of us have around floor coverings.

-

Posted: August 26, 2020||Read more »Digital transformation continues to be a hot topic for businesses as it is a proven way for companies of any size to leverage innovative new technologies and significantly reduce costs, while also improving operations, performance, safety and, ultimately, the bottom line. These efforts might begin with a focus on one part of a company, but the benefits can extend throughout the organization and externally to customers and partners.

-

Read more »When performing vital tests in hospitals or clinical labs, results must be accurate and quick. Prescribed medical care for individuals, or decisions that could impact large groups of people, are depending on these results and no one wants a delay.

-

Read more »From songs to books to entertainment and common phrases, there are no shortages of rings to discuss. The same holds true for today’s manufacturers. They want to conserve floor space by developing circular or complex curvilinear paths for product movement within production workstation cells and must choose between using slewing rings or vee guide ring systems. Multiple ring options, but what is the best choice? As with most situations, both products have their benefits and best use cases.

-

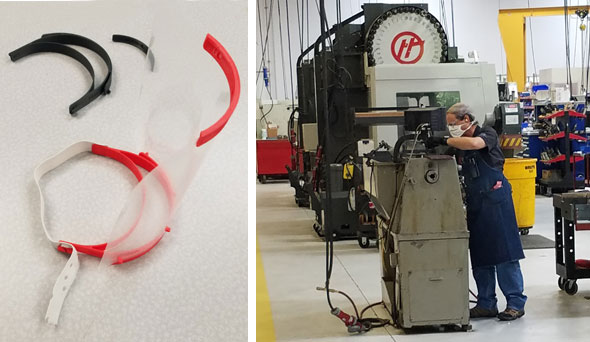

Read more »Located in Pittsburg, California, Bishop-Wisecarver (BW) has been under a Shelter in Place order since March 17. Like everyone else throughout the world, COVID-19 has changed nearly every aspect of our “normal” ways of doing business, but as a team, we’ve found new solutions to meet these challenges. And we’ve found those silver linings throughout the process as we’ve continued to manufacture linear motion products daily and provide our Signature Experience for customers.

-

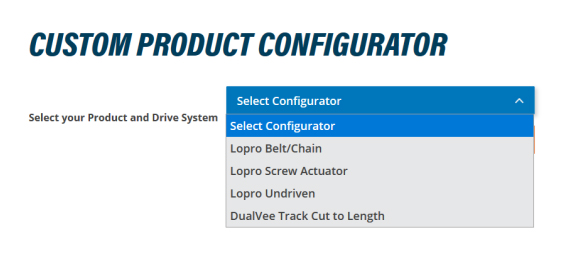

Read more »Helping customers quickly is always a priority for Bishop-Wisecarver (BW), but we also want to ensure the best solution for each specific project. What good is fast if it doesn’t solve the problem? With the new Product Configurator customers get both speed and accuracy as the entire process takes approximately 5 minutes and includes CAD drawings, LoPro® actuator product descriptions and even specific stock codes to make the online ordering easier.